You either get the values that were in effect before the G71 was called, or you may specify one or more of these using the F, S, or T words on the G71 itself. Only one feedrate, spindle rpm, and tool is valid for G71. Some controllers also have a “Semi-finish” allowance specified by the I and K words that is used for one final pass with the roughing tool. This is done with the U word for the X finish allowance and the W word for the Z finish allowance. It’s convenient to tell G71 how much stock to leave behind for finishing.

#Ncplot trial code

You can use a G70 or other code (more on that in another article) to perform a finishing pass. If you specified G00, it rapids down to the prior cut depth and then goes to G01 for the remainder of the feed. It must be one or the other! Whichever one you use, that’s what the controller will use to partially feed on each pass. In addition, the controller notices whether that move is made as a G00 or G01. The move there is not part of the profile, but allows you to move the cutter to the starting point of the profile. The first profile block, the one specified by the “P” word, is special.

In Type I, a retract is done on a 45 degree angle from the cutting pass, and then the cutter returns to the starting Z position using rapids speed before feeding down to the next pass. If you’re using G-Wizard Editor to simulate G71’s, you get to specify the retract in the Post.įor this section, we’ll describe only Type I, and will cover Type II below.

For Haas machines, that’s Setting 73, and the default value is 0.05″. One the one line, the amount of retraction is in a setting. With the 2-line form, you can control the retract move using the “R” word to specify how much to retract. Roughing passes proceed until they hit the profile or the edge of the profile’s bounding box, and then they perform a retract move and go back for the next pass. This is the distance between successive roughing passes.

#Ncplot trial manual

If you want to do something more than just lines and arcs, you’ll want to consult your controller’s programming manual to be sure it is allowed.įor two line format, the rough depth is specified by “U”. There are quite a few restrictions on what can happen on those lines, so it’s best to keep them simple. The “P” word is the “N” number of the first line of profile G-code and the “Q” word is specifies the last line. The first thing that has to be done is to tell the G71 where it can find the g-codes that create the profile. Specify the Profile Blocks With “P” and “Q” Words Now let’s compare the two and see what the different words do for each. % Top to bottom, right to left G0 X4 Z1.0 (Start Position before commanding the cycle) G71 U1.0 R0.5 G71 P1 Q4 F2 U0.2 W0.1 N1 G0 X1.6 N2 G1 Z-4.0 N3 X2.5 Z-5.0 N4 G1 X4 Here is the same program set up for the “2 line” syntax: The example given above was a “1 line” format. The two are only slightly different and for the most part they have the same capabilities. If you have a Fanuc 10T, 11T, or 15T, or you have a Haas, it probably uses the 1 line syntax. If you have a later model Fanuc control, it probably has 2 line syntax. – They can be either Type I or Type II, with Type II being capable of cutting “Pockets” – They can be either 2 line or 1 line syntax. There are essentially two ways in which G71 cycles vary from one controller to the next. What Kind of G71 Does Your Controller Have?

#Ncplot trial how to

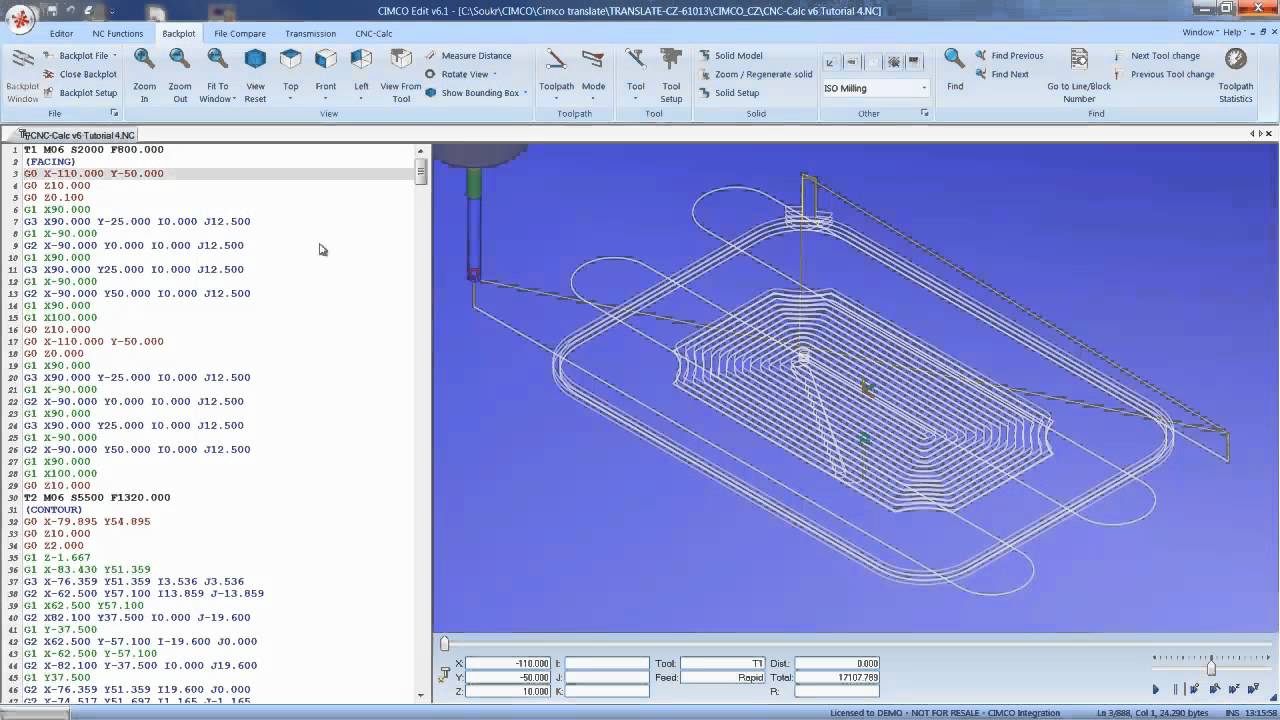

Before we dive into exactly how to program a G71, we need to cover the different flavors of G71 you may run into. G71 can save you a whole bunch of time and make it pretty easy to crank out some parts without needing to access a CAM program. There’s not much more needed than the profile to get the job done. % Top to bottom, right to left ( One line G71 ) G0 X4 Z1.0 (Start Position before commanding the cycle) G71 P1 Q4 D1.0 F2 U0.2 W0.1 N1 G0 X1.6 N2 G1 Z-4.0 N3 X2.5 Z-5.0 N4 G1 X4 The simulated G71 makes 2 roughing passes and then cuts the profile… Now here is a simulated G71 command to rough turn that profile: The code associated with the profile is trivial: This profile consists of 3 G01 line segments with a G00 rapid move to the starting point of the profile. The difference is that instead of specifying a profile in a CAD program, you specify the profile using g-codes.Ī simple profile consisting of 3 G01 segments with a G00 to the starting point… G71 and its cousins are some of the most useful canned cycles you’ll ever come across for the lathe, because they essentially do what I’ve just described.

You draw the profile that you want to turn on a part, push a button, and out comes g-code that converts that profile into the right moves to cut the profile in multiple passes based on the depth of cut for each pass you specified. Imagine how a CAM program might work for the lathe.

0 kommentar(er)

0 kommentar(er)